Developing Chemical Products

Precious metals find wide-ranging applications in the field of chemistry because of their excellent corrosion resistance, heat resistance, and catalytic activity. Based on a comprehensive understanding of product functionality and structure, we customize our products for the clients' application or develop them assuming the actual conditions in which they will be used.

Insoluble Electrodes: Customization for Diverse Applications

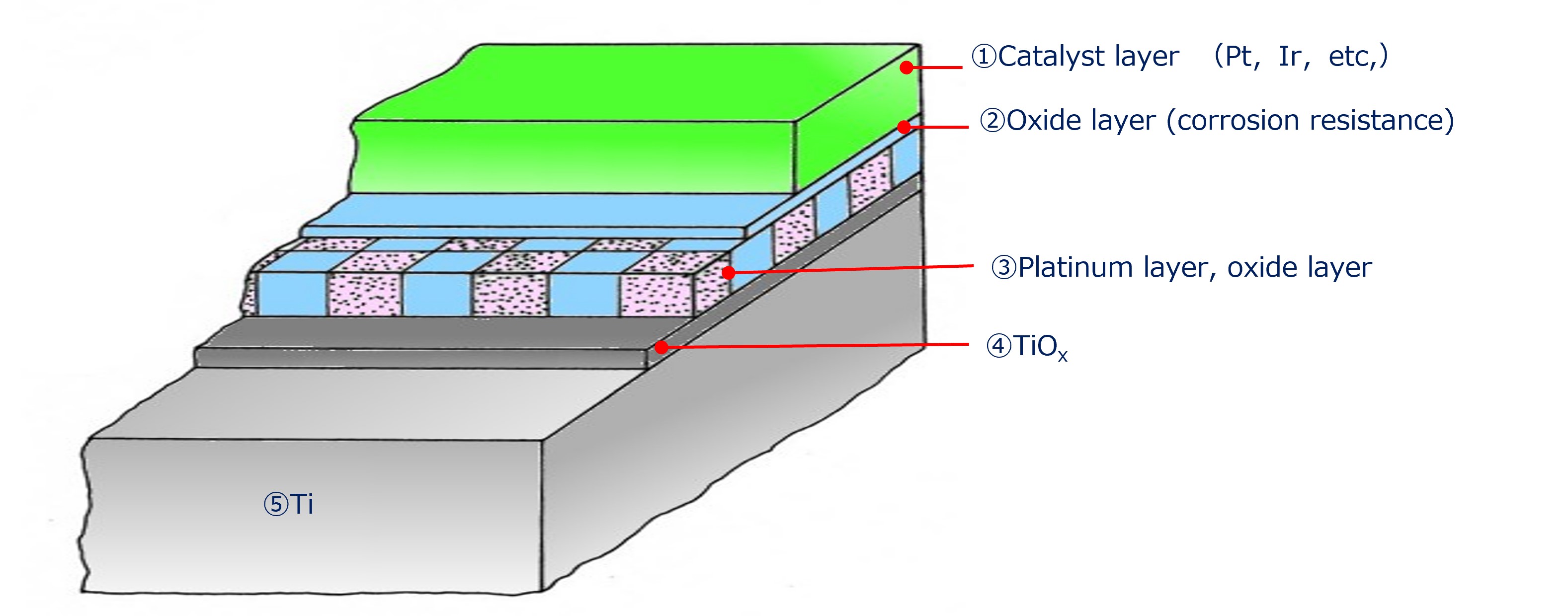

Since its introduction in 1983, our oxidized iridium coated titanium electrode has been widely used in various applications, including large-scale plating lines, industrial chlorine generators, and hypochlorous acid generation devices. The electrode is composed of multiple functional layers, each serving a distinct purpose. By adjusting the combination and composition of each layer, it can be enhanced in terms of durability, electrode activity, cost-performance, and more. This enables us to design customized electrodes that precisely meet our clients' needs.

Platinum Paste: Pursuing High Reliability

Conductive paste is a material primarily used for printing electronic circuits onto substrates. In particular, precious metals pastes, such as platinum pastes, are frequently used in demanding environments where high reliability is required. The reliability of pastes depends on multiple factors, including the ability to print accurately and uniformly, strong adhesion between the circuit and substrate, stable electrical resistance, and prevention of circuit breakage.

We prepare various types of precious metal powders in-house for paste development. Through the optimal combination of different aggregate components and solvents, we create products that exhibit high reliability in the intended usage environments.

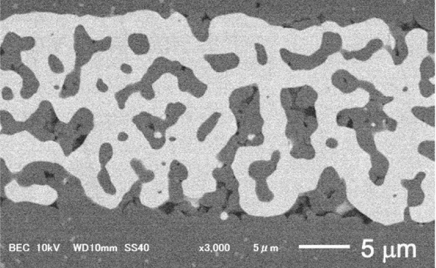

White represents platinum, and gray represents ceramic.

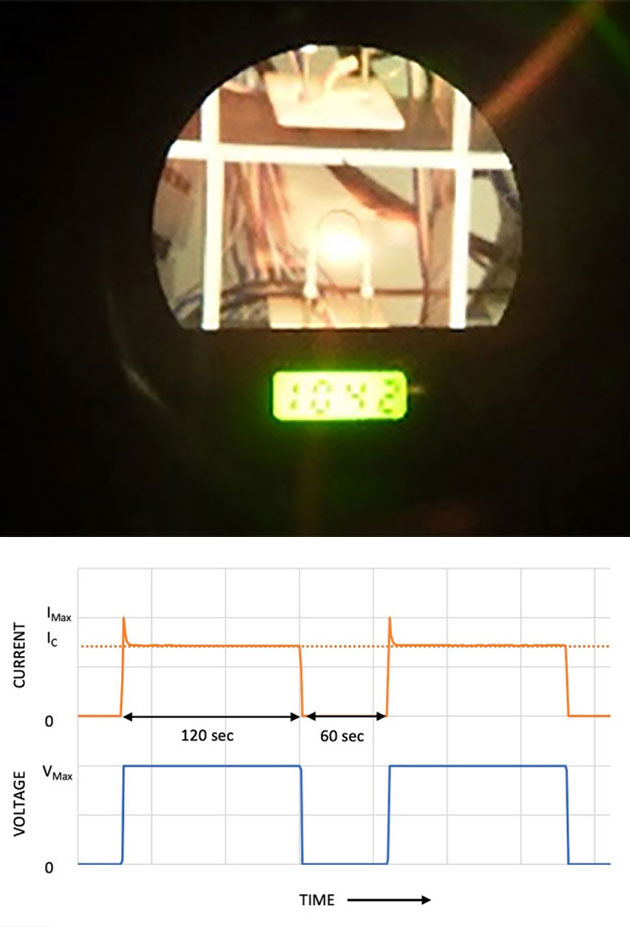

Furthermore, we have designed our own durability evaluation equipment, which enable us to conduct pastes assessment that simulate the stress conditions caused by changes in heat and current. Through the application of this equipment in paste design, we have successfully optimized the fine structures formed by precious metal powders and additive components, resulting in a tenfold improvement in durability compared to conventional products while maintaining high conductivity.

The forgoing development of the paste was carried out in collaboration with the technical cooperation of Tokyo Institute of Technology, our industry-academia partner. The fundamental research findings that formed the basis of the paste development were authored as a paper by Professor Fumihiro Wakai of the university and published in the British scientific journal "Acta Materialia."